Indice dei contenuti

ToggleMany operations of warehouse I'm still at the beginning of the adoption curveautomation, looking for solutions to remain productive, profitable and competitive.

In recent years, thanks to the rapids market evolution, bottlenecks and stresses in supply chain however, they have reached a critical state.

Interest in warehouse automation, as a result, has reached new heights.

This is also due to theincrease in demand for goods pandemic-induced, combined with a labor shortage increasingly evident, revealing fault lines in today's supply chain infrastructure and straining it in unprecedented ways.

Companies, therefore, try to to adapt to an ever-changing landscape, and are accelerating the pace at which they accept and adopt new trends And technologies.

Trends driving automation: Near sourcing (or Nearshoring)

Speak about increase in productivity it might seem trivial, yet it is the reason that originally moved companies to automate their warehouses.

They are there though other reasons, more recent, which are giving the driving force to the introduction of increasingly sophisticated technologies in operational flows.

It is the market, with its new needs, that is calling companies towards one greater flexibility and ability to adapt to demand. A question that requires first of all speed.

As proof of this, we can see how trends such as that of the near sourcing, which required a rethink of warehouse processes.

Near sourcing, in fact, is a practice designed to maintain the customers satisfied with delivery times speeds they expect from retailers by locating certain order fulfillment operations closer to their final destinations with customers.

And the products today they must move more quickly, due to shorter life cycles, increasingly fickle consumer tastes and, consequently, rapid changes in the products themselves.

More specifically, near sourcing (or “nearshoring") it's a sourcing strategy and manufacturing where a company decides to move part of its operations or manufacturing activities to a location geographically close to or relatively close to its headquarters.

This choice is opposed to the concept of "outsourcing", which involves the relocation of operations to very distant countries, often with low-cost labor.

There are many reasons that push more and more large companies, including Amazon, to adopt nearshoring. However, focusing on warehouse and therefore logistics logics, we can identify 3 main reasons:

- Proximity to the market: By getting closer geographically to target markets, companies can reduce delivery times and time to market, responding more quickly to customer needs.

- Reduced costs: While near sourcing may result in slightly higher production costs than outsourcing to low-cost countries, it can still help keep logistics and supply chain management costs down, while also reducing the risks associated with overly long supply chains and complex.

- Quality and flexibility: Geographic proximity facilitates the control and monitoring of product quality. Furthermore, it is easier to make rapid changes or adaptations to production in response to market needs.

Automation and human work, aligning with Industry 5.0

Warehouse work has always been challenging for people, because it involves lifting and lowering heavy loads, repetitive motions that leave the body prone to injury, and extreme temperatures in both summer and winter.

However, many warehouse tasks still remain manual and companies are still struggling gradually equipping itself to automate these operations.

If with theIndustry 4.0 has been given the green light for digital transition and automation in businesses, a new push comes from the new paradigm of Industry 5.0.

At the center of this fifth industrial revolution, more precisely, there are sustainability And resilience, but above all a human-centric approach.

This means that advanced technologies are used to improve the life and work of operators. Furthermore, we try to create a working environment Safe and comfortable, where operators can carry out their activities efficiently and satisfactorily.

If theIndustry 4.0 it has therefore been characterized by connection and digitalisation, with the consequent creation of intelligent factories (Smart Factory), the objective ofIndustry 5.0 is that of take the next step.

This consists in truly taking full advantage of the collaboration between increasingly powerful technologies and human beings, adopting a completely new approach, human-centric precisely.

What are the technologies for the future of warehouse automation

There are many products on the market aimed atautomation, which however tend to be components rather than complete solutions.

For example, i autonomous mobile robots (AMR) they transport goods from point A to point B but lack handling capabilities, requiring some other piece of automation or a person to complete a job.

THE robotic arms, in turn, often need expert programmers, while i vision systems for bin picking they address some of the most dynamic challenges in the work cell, but are often specialized to address a particular application.

Safety components such as fences, collision avoidance sensors, emergency stops and lidar protection are also essential to keep people safe around operating robots.

Creating an end-to-end solution, however, requiresunion of these tools with complex and expensive system integration. Furthermore, these solutions often also occupy large and precious floor spaces in the warehouse.

These reasons motivate the emergence of more fascinating and powerful technologies, such as mobile collaborative robot.

The classic static production lines, based on traditional robotics, are in fact rapidly moving away to make room for a new generation of robots intelligent, autonomous and mobile.

It is precisely these three characteristics that make them capable of moving in the environment and interacting with the objects that populate it with millimeter precision, but also to easily adapt to new assigned tasks, ensuring absolute flexibility.

The same thing goes for theinteraction with human beings, the real strong point of these robotic solutions which are fully included among the technologies enabling the new paradigm ofIndustry 5.0.

TOD System accepted the challenge

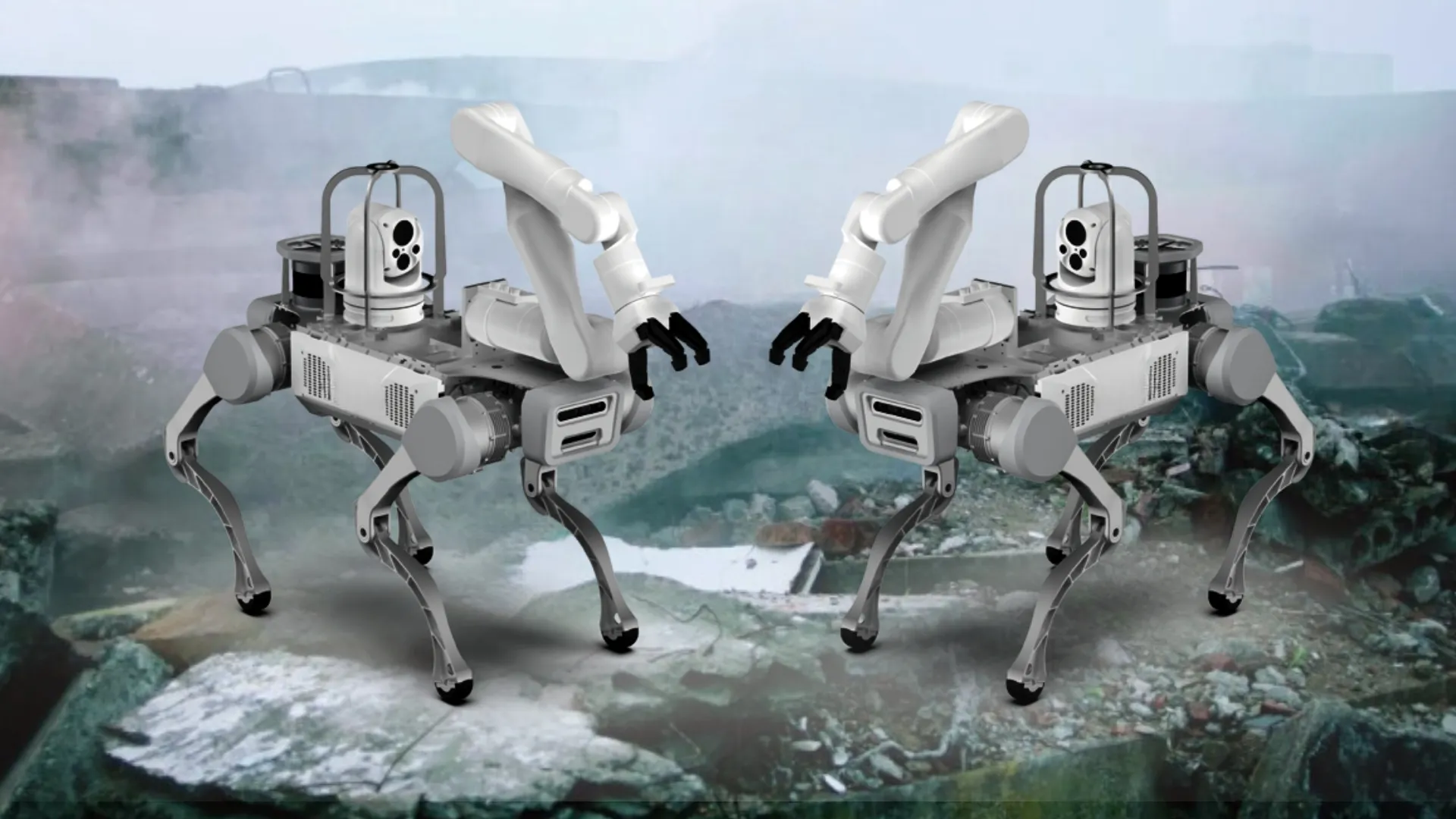

Mobile collaborative robots are transforming the way businesses approachindustrial automation.

These autonomous mobile robots offer a wide range of advantages, allowing safe and efficient collaboration between men and machines, as well as perfect optimization of goods flows within warehouses.

For this reason, in TOD System, we study definitive solutions for every need.

todrobot TR1 it is the solution designed to consolidate itself as a indispensable partner to free human employees from repetitive, heavy, dangerous or requiring higher execution precision.

At the basis of our project is the intention to provide a unique tool capable of fulfilling many functions, in full respect of human work and the principles ofIndustry 5.0.

In TOD System, therefore, we have developed a mobile collaborative robot completely autonomous and customizable, small in size and easy to reprogram and position even in small warehouses.

We use the best technologies on the market to guarantee our customers the possibility of adapting TR1 to every operational need.

Thanks to the study in terms of Robotic Vision, conducted by our research and development department, todrobot TR1 is able to recognize the packages and objects it works with, to reduce errors in logistics processes

The great versatility, however, is guaranteed by a management software capable of integrating our solution in every context and to coordinate the most advanced technologies for carrying out activities.

In short, todrobot TR1 and the definitive solution for logistics warehouses of all sizes. It seems impossible? Instead it is already a reality.

Contact us to learn more about our revolutionary project and all the solutions we can offer.