Indice dei contenuti

ToggleIn the era of modern industrial automation, one of the most fascinating and powerful emerging technologies is represented by mobile collaborative robot.

These advanced robotic systems are changing the face of factories and industries around the world, offering a variety of unprecedented benefits.

The factories of the future, after all, require highly flexible technologies, and this is why mobile robotics is becoming leading actress of progress.

The classic static production lines, based on traditional robotics, are in fact rapidly moving away to make room for a new generation of robots intelligent, autonomous and mobile.

It is precisely these three characteristics that make them capable of moving in the environment and interacting with the objects that populate it with millimeter precision, but also to easily adapt to new assigned tasks, ensuring absolute flexibility.

The same thing can be said for the interaction with the human being, the real strong point of these robotic solutions which are fully included among the technologies enabling the new paradigm ofIndustry 5.0.

In this article, therefore, we will try to define what mobile collaborative robots are, how they work, what they can do, the sectors in which they are used and why they have become so indispensable in companies.

What are Mobile Collaborative Robots and what can they do?

THE mobile collaborative robot they are autonomous mobile robots designed to interact safely and cooperatively with humans in the work environment.

Unlike traditional industrial robots, which operate in isolated areas and are separated from human workers by physical barriers, these robots are designed to working side by side with people in a direct and collaborative way.

Mobile collaborative robots are capable of carrying out a wide range of tasks within different industries. They can be used for assembly work, packaging, labeling, material handling, quality inspection, product testing, and much more.

Thanks to their ability to safe interaction with humans, they can also support and assist human operators in daily tasks, increasing efficiency and reducing errors.

Autonomy And flexibility these are the strong points of these solutions which, in addition to being able to interact perfectly with the surrounding environment, can adapt to any type of task assigned to them and any production context.

This is for two reasons, which we will explore further in the next lines of this article.

The first is that mobile collaborative robots are equipped with vision systems and sensors through which they "see" the world and interact with it by evaluating the best action also on the basis of previously collected data.

The second is that these solutions are designed to be able to be moved manually or to be simply "sent" to another location without the need for complicated reprogramming.

In this way, and by providing them with only the right indications and tools to carry out the different operations, mobile collaborative robots can help make the business processes of different operational areas more efficient and faster in the same work cycle.

How Do Mobile Collaborative Robots Work?

Mobile collaborative robots are equipped with advanced sensors And intelligent algorithms which allow them to perceive their surroundings and react accordingly.

They use a combination of technologies such as artificial vision, the autonomous navigation, the route planning and themachine learning to move safely around the work environment, avoiding obstacles and people along the way.

Thanks to their simple and flexible programming, these solutions are able to quickly adapt to new situations and tasks.

For human operators, the interaction with robots is made agile and smooth by the use of intuitive interfaces such as touch screens, voice commands, but also and more simply by moving them manually to teach them new movements or positions.

In the warehouses and factories where they are placed, mobile collaborative robots they do not require environmental enrichment, which means being able to metaphorically insert them in "plug & play" within the production cycles, without further investments to align the spaces.

A great advantage especially for companies that have limited spaces but who would like to implement truly effective automation.

Effective because mobile collaborative robots, once started to work, are truly able to work without having to be constantly followed or monitored.

Some have advanced systems Robotic Vision which, in fact, allow them an impeccable recognition of the objects with which they have to interact, excluding errors and guaranteeing reliability in carrying out the assigned tasks.

Which are potentially infinite, but we will also delve into this later.

The technologies behind Mobile Collaborative Robots

Mobile collaborative robots, we have already explained, are based on a combination of different advanced technologies that allow them to operate autonomously and cooperatively.

However, we want to go into a little more detail to provide more technical interpretations of the key technologies that underlie the functioning of mobile collaborative robots.

Right away:

Advanced sensors

Mobile collaborative robots are equipped with a wide range of sensors that allow them to perceive the environment surrounding. These sensors include cameras, depth sensors, ultrasonic sensors, touch sensors and many more.

Through the use of sensors, robots are able to detect objects, people and obstacles in the work environment, allowing them to safely navigate and interact precisely with human operators.

Artificial vision

Computer vision is a key technology for mobile collaborative robots. Using high-resolution cameras and computer vision algorithms, robots are capable of recognize objects, people and visual signals in the environment.

This allows them to identify and locate objects to manipulate, detect and track people's movements, and understand their surroundings to avoid collisions.

Autonomous navigation

Mobile collaborative robots are equipped with autonomous navigation systems that allow them to move safely and efficiently in the work environment. Using sensors and maps of the environment, robots can plan optimal routes, avoiding obstacles and people along the way.

Some robots also use technologies such as simultaneous localization and mapping (SLAM) to create maps of the environment in real time and to adapt to changes in the environment without the need for additional markers or infrastructure.

Artificial intelligence and machine learning

Artificial intelligence and machine learning play a vital role in mobile collaborative robots. Through intelligent algorithms, robots are able to learn from data and improve their performance over time.

They can adapt to new situations, optimize navigation paths, improve object manipulation skills and even predict needs of human operators.

The integration of artificial intelligence allows robots to make autonomous decisions, improving the efficiency and adaptability of their activities.

Intuitive interfaces

Mobile collaborative robots feature intuitive interfaces that allow human operators to interact with robots easily and naturally. These interfaces can be touch screens, voice commands or even manual gestures.

This makes it easier to program the robots, teach them new movements and monitor their activities.

Together, these technologies enable mobile collaborative robots to operate safely, efficiently and collaboratively within industrial work environments, bringing significant benefits to the companies that employ them.

In which sectors are Mobile Collaborative Robots used?

Mobile collaborative robots find application in various industrial sectors, such as automotive, electronics, food industry, logistics and many others.

In the automotive sector, for example, they are used for component assembly, welding, vehicle inspection and internal logistics management.

In the food sector they can be used for selecting and packaging products, preparing meals, cleaning and sanitizing work environments.

In the logistics sector they can be used for handling and preparing orders, loading and unloading products, and even for the autonomous delivery of items within a warehouse or distribution center.

What they can do, however, is potentially limitless.

In fact, by providing a mobile collaborative robot with the right tools, they can be put to work for the most diverse tasks. Between these:

Assembly

These solutions can automate assembly processes, a fundamental operation for obtaining precision, reducing execution times and reducing costs in operations such as screwing, fixing and inserting parts.

Movement

The context of goods handling is broad and includes a series of extremely repetitive and, in some cases, even heavy and dangerous operations. For this reason, mobile collaborative robots are designed to carry out these tasks, relieving the burden on human operators and guaranteeing maximum precision, greater speed and great flexibility in their execution. From pick & place to packaging, from palletizing to picking from the bin to labelling, and beyond.

Machine tending

Mobile collaborative robots relieve human operators in charge of tending machines from all those repetitive and tiring jobs that increase the risk of accidents at work, significantly improving the times and quality of the process.

Quality check

Robots allow you to automate quality control by improving consistency measurement and maintaining high product standards. The extremely repeatable execution of programmed processes and predefined workflows, which only robotic solutions of this kind guarantee, create optimal conditions for the study and analysis of products.

Material removal

Grinding, deburring, milling, drilling and other material removal tasks can benefit greatly from the versatility of mobile collaborative robots which, when inserted into production lines, bring flexibility and efficiency to the processes, also allowing a clear reduction in waste.

Delivery

These robotic solutions are perfectly suited to gluing, sealing, painting and any other activity that includes dispensing.

Surface finish

Mobile collaborative robots guarantee precision in all those operations that require force regulation and a sometimes delicate touch. This is the case for special finishing operations such as polishing, sanding and sandblasting.

Welding

Collaborative robots are capable of carrying out and managing welding operations of all kinds: arc, laser, ultrasonic, brazing, TIG, MIG, plasma and spot. Our solutions increase the flexibility, efficiency and versatility of these processes, ensuring the ability to manage and optimize higher workflows. Furthermore, by relieving human operators from these often dangerous operations, they improve workplace safety.

Why Mobile Collaborative Robots are Indispensable in Companies

Mobile collaborative robots have become indispensable for companies for several reasons.

First of all, the integration of these solutions into production processes allows a significant increase inefficiency and of productivity. That's because they can work continuously, reducing cycle times and enabling continuous production.

Furthermore, they reduce the risk of human errors, improving the quality of work and reducing waste and delays.

And again, their ability to work safely close to human operators allows for make the most of people's skills and experience, improving ergonomics and job security.

Finally, being highly flexible, mobile collaborative robots can be easily repurposed to perform new tasks or adapt to changes in the production process.

This allows companies to be more responsive to market needs constantly evolving and maintaining a competitive position.

Our definitive solution: todrobot TR1

Mobile collaborative robots are transforming the way businesses approachindustrial automation.

These autonomous mobile robots offer a wide range of advantages, enabling safe and efficient collaboration between humans and machines, and have therefore become indispensable in many industrial sectors thanks to their ability to improve efficiency, work quality and production flexibility.

For this reason, in TOD System, we study definitive solutions for every business need.

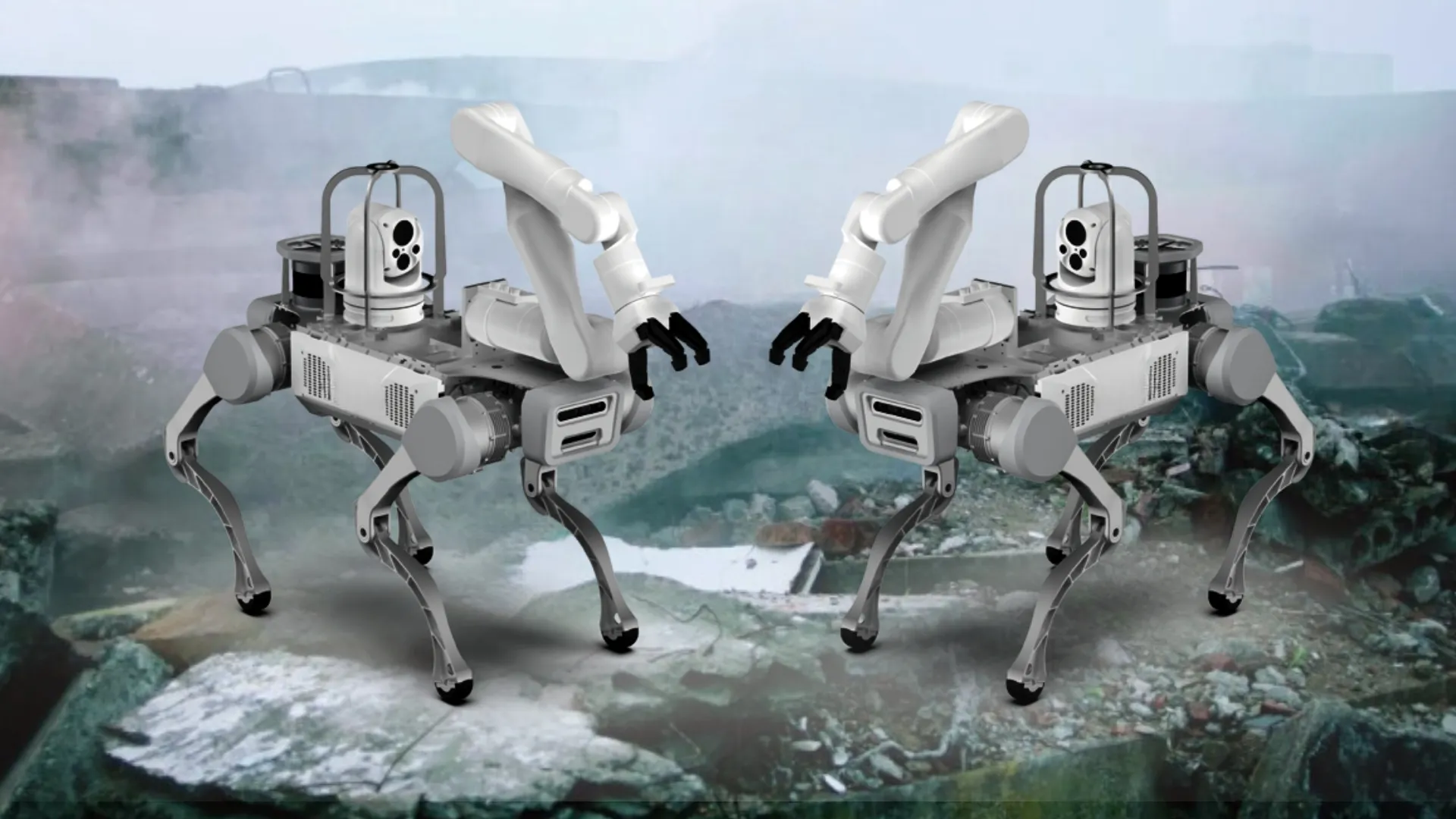

todrobot TR1 is the solution designed to provide answers to every operational need, consolidating itself as a indispensable partner to free human employees from repetitive, heavy, dangerous or requiring higher execution precision.

At the basis of our project is the intention to provide a unique tool capable of fulfilling many functions, in full respect of human work and the principles ofIndustry 5.0.

In TOD System, therefore, we have developed a mobile collaborative robot completely autonomous and customizable, small in size and easy to reprogram and position even in small company spaces.

We use the best technologies on the market to guarantee our customers the possibility of adapting TR1 to every operational need.

The great versatility, however, is guaranteed by a management software capable of integrating our solution in every industrial context and to coordinate the most advanced technologies for carrying out activities.

In short, todrobot TR1 and the definitive solution for every business need and for all types of companies.It seems impossible? Instead it is already a reality.

Contact us to learn more about our revolutionary project and all the solutions we can offer.