Indice dei contenuti

ToggleOver the years, the management of the warehouse has become an increasingly complex business, requiring increasingly advanced solutions to ensure maximum effectiveness and efficiency.

Coming to the companies' rescue was the WMS, acronym for "Warehouse Management System", or a system of warehouse management which deals with the automation of internal processes, from receiving goods to shipping.

However, due to the rapid and dizzying market developments, the traditional WMS is leaving more and more space for a new, even more advanced solution, capable of aligning companies with the new market paradigms: the Smart WMS.

For this reason, in the following lines, we will explore the path that led from the adoption of WMS systems to Smart WMS, focusing on the main differences between the two, but above all on the characteristics and benefits that make Smart WMS the perfect allies for the creation Of warehouses 4.0 in line with the paradigms of logistics 4.0 And industry 4.0.

Evolution of WMS

The history of WMS dates back to the 1960s and 1970s, when computers were introduced into warehouses to help manage inventory.

However, early WMSs were limited and often required manual data input. Throughout the 1980s and 1990s, WMSs became more sophisticated, integrating features such as order tracking and inventory management. By 2000, WMS had become the norm, with most warehouses using computer-based warehouse management systems.

At the basis of the evolution into Smart WMS, however, there was the need, as always, to go beyond and to exploit the advent of new technologies such asInternet of Things (IoT), L'Artificial intelligence (TO THE) and technology RFID.

Today, Smart WMSs are becoming more and more common, with many companies adopting them for optimize warehouse management.

This is because a Smart WMS combines the functionality of traditional WMS with the latest technologies, offering greater efficiency, precision And visibility inside the warehouse.

What are the main differences between WMS and Smart WMS?

Let's start by saying that a traditional WMS focuses on managing warehouse activities such as order processing, receiving goods, inventory and shipping products.

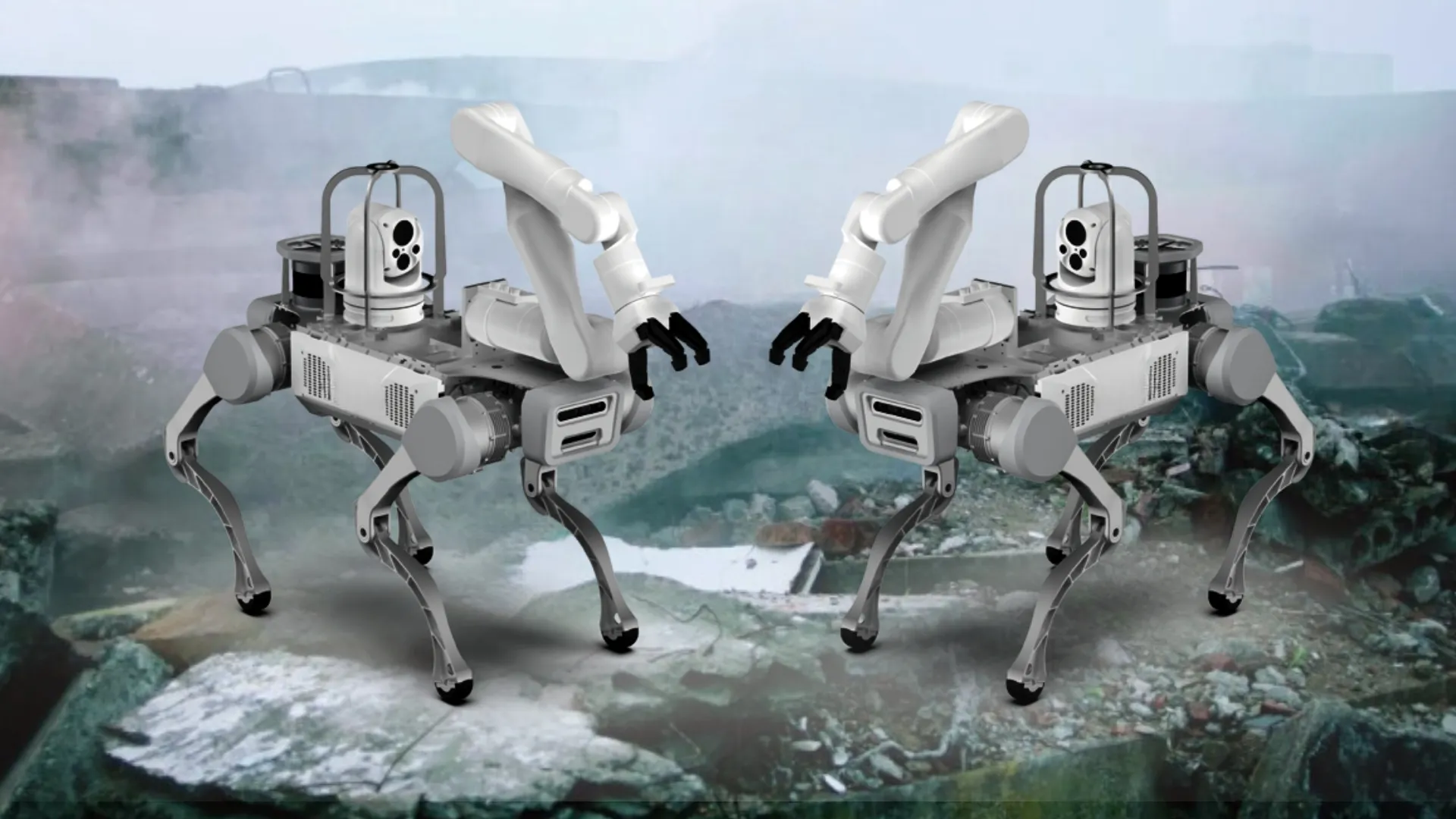

However, with the increasing use of technologies such as robotic logistics, L'IoT and theArtificial intelligence, companies are increasingly turning to the adoption of inventory management systems Smart WMS.

The reason is simple: to improve the efficiency of their warehouse operations and grab a competitive advantage on the market.

A smart WMS inventory management system, in fact, uses advanced technologies such as Machine Learning and theTO THE to analyze and forecast inventory and merchandise flow trends, improving forecast accuracy and minimizing lost sales and inventory waste.

Furthermore, thanks to System Integration, it is possible to interact with the technologies that make up the whole robotic line of a warehouse, including i Cobots, but also RFID and IoT sensors, to further automate warehouse processes.

Integration with other technologies clearly improves warehouse efficiency and minimizes human errors, leading to increased productivity and cost savings.

But a smart WMS inventory management system can also offer functionality data visualization advanced, allowing warehouse managers to monitor inventory in real time.

Features of the Smart WMS

To better understand the differences just mentioned, and above all the regions that push companies to move from traditional warehouse management systems to Smart WMS, it is therefore appropriate to indicate some fundamental characteristics.

Among these, we can identify at least 5 that make Smart WMS indispensable allies for every company:

Automation of warehouse processes

One of the main advantages of Smart WMS is the ability to automate warehouse processes, minimizing errors and increasing the efficiency of operations.

For example, the software can automatically manage the movement of items within the warehouse, assigning them a place based on demand and rotation, and automatically planning the movement of incoming and outgoing items.

Use of advanced technologies (IoT, AI, RFID, etc.)

The Smart WMS leverages advanced technologies such as IoT, AI, machine learning and RFID to collect and analyze data in real time and provide solutions to improve warehouse management.

For example, IoT sensors can collect data on item movements within the warehouse, while RFID readers can identify individual items and precisely track them within the warehouse.

Real-time control and monitoring

The Smart WMS offers real-time control and monitoring of the entire warehouse, thanks to the ability to collect and analyze data in real time.

This allows you to identify any problems or inefficiencies and take immediate action to resolve them, improving the overall efficiency of the warehouse.

Intuitive and customizable user interface

Another important feature of the Smart WMS is the intuitive and customizable user interface, which allows warehouse managers to access the information and functionality they need quickly and easily.

Additionally, the user interface can be customized to specific warehouse needs, offering greater flexibility in using the system.

Optimization of inventory management

Finally, the Smart WMS offers greater optimization of inventory management, thanks to the ability to collect and analyze data in real time and provide solutions to improve item allocation and stock rotation.

This helps minimize waste and increase overall warehouse efficiency.

The Advantages of a Smart WMS

What has been said so far could already be enough to understand what the main ones are advantages of a Smart WMS for warehouse management.

Nonetheless, the benefits of Smart WMS deserve to be listed individually, to better understand how they can positively impact crucial aspects of every business.

From operational efficiency to end customer satisfaction.

Greater operational efficiency

The Smart WMS uses technology to automate many warehouse processes. This means that manual tasks, such as receiving and processing orders, picking and shipping, can be handled automatically by the system, reducing lead times and increasing operational efficiency.

Better inventory management and error reduction

Smart WMS allows you to manage inventories more precisely and efficiently than traditional WMS. Thanks to process automation and real-time item tracking, the system is able to constantly monitor the location and status of items, minimizing counting errors and the risk of loss or theft.

Greater visibility and control over warehouse activities

The Smart WMS gives warehouse managers greater visibility and control over warehouse activities, allowing them to have a complete overview of warehouse operations in real time. Additionally, Smart WMS software can generate automated reports that allow warehouse managers to quickly identify inefficiencies and take immediate action.

Improved customer satisfaction and loyalty

Greater operational efficiency and reduction of errors lead to greater satisfaction and therefore customer loyalty. When customers receive their shipments quickly and accurately, they are obviously more likely to return to purchase from that supplier again. Additionally, Smart WMS software allows you to provide your customers with real-time shipment information, including updates on shipment progress and expected delivery date.

Reduction of warehouse management costs

A Smart WMS automates many of your warehouse tasks, reducing the need for human staff to perform these tasks. Additionally, the software can help prevent costly errors that can occur when warehouse tasks are performed manually.

Improved forecasts

Using advanced data analytics technologies, such as Machine Learning and Artificial Intelligence, Smart WMS systems can analyze historical inventory data, predict future trends and necessary inventory levels.

This means businesses can avoid losing sales due to inventory shortages or overstocking with too much inventory, which can cause storage and waste issues.

Finally, thanks to the ability to make more precise forecasts, companies can also more effectively schedule the delivery of products to customers, reducing waiting times and increasing customer satisfaction.

Relying on the right partner makes the difference

Implementing a Smart WMS takes time and resources, but the benefits to your business can be significant.

The choice of right technological partner, the definition of a detailed planning and the training adequate staffing they are therefore fundamental for correct implementation of the system.

In TOD System we take care of every aspect of the digital transformation of warehouses, providing robotic solutions advanced and customized to the needs of each company.

Thanks to our WMS, e smart WMS, we help businesses with theirs digital transformation, supporting them at every stage of the design.

From development, to training, assistance and technical consultancy.